Magnetic Particle Testing Equipment

Magnetic Particle Testing (MPT) stands as a robust inspection technique employed for identifying surface and subsurface irregularities in ferromagnetic materials. Integral to Third-Party Inspection services, MPT assumes a vital role in ensuring the quality, safety, and durability of a diverse range of products and components.

The Need for Magnetic Particle Testing

In the contemporary competitive market, the paramount importance of product integrity and reliability is evident. Magnetic Particle Testing, when carried out by an unbiased third party, emerges as a reliable method to:

- Identify Potential Weaknesses: Uncover cracks, seams, and other flaws that could impact performance.

- Assure Compliance: Verify that products adhere to regulatory requirements and industry standards.

- Build Confidence: Foster customer trust by showcasing a dedication to quality.

- Reduce Risks: Mitigate the risk of future failures, thereby minimizing both downtime and liability.

- Enhanced Product Quality: Detecting flaws early on contributes to the production of superior products.

- Improved Operational Efficiency: Decreased downtime and maintenance costs result in heightened efficiency.

- Elevated Reputation: Acknowledgment for adherence to quality, environmental, and safety standards enhances reputation.

- Risk Mitigation: Identifying hidden defects helps prevent potential hazards and mitigates risks.

Process of Conducting Magnetic Particle Testing

Our methodical approach guarantees the utmost precision and dependability:

- Test Surface Preparation: Eliminating dirt, paint, or coatings to ensure a clean surface.

- Magnetic Field Application: Generating a magnetic field within the material through an appropriate magnetizing technique.

- Particle Application: Applying magnetic particles that are drawn to areas with magnetic flux leakage.

- Examination: Thoroughly inspecting the test surface under suitable lighting to identify indications.

- Interpretation and Evaluation: Analyzing indications to determine their relevance to quality and safety.

- Demagnetization: Eliminating the residual magnetic field.

- Documentation: Creating a comprehensive report containing findings, recommendations, and compliance status.

Magnetic Particle Testing within the framework of Third-Party Inspection transcends routine procedures; it represents a strategic approach to both quality control and risk management. Utilizing our specialized services empowers organizations to make informed decisions, promote ongoing improvement, and maintain a competitive advantage.

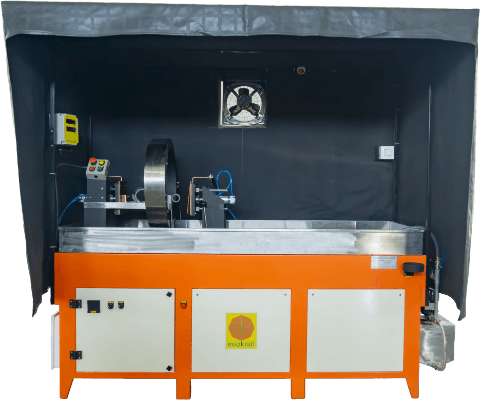

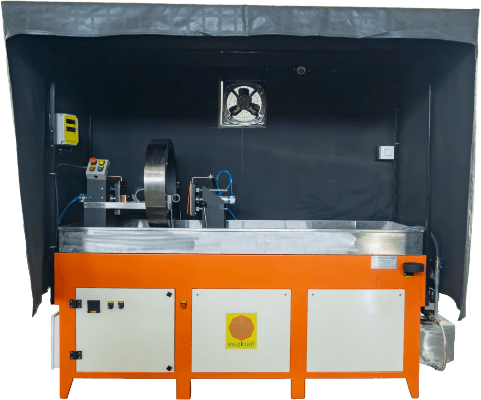

Standard MPI Machine

Our standard MPI test bench units establish the benchmark for MPI inspection, setting a high standard. They find application across a diverse range of industries, including automotive, fasteners, hand tools, oil field equipment, railways, and education & training for the detection of surface & subsurface defects. These benches operate as two-vector machines.

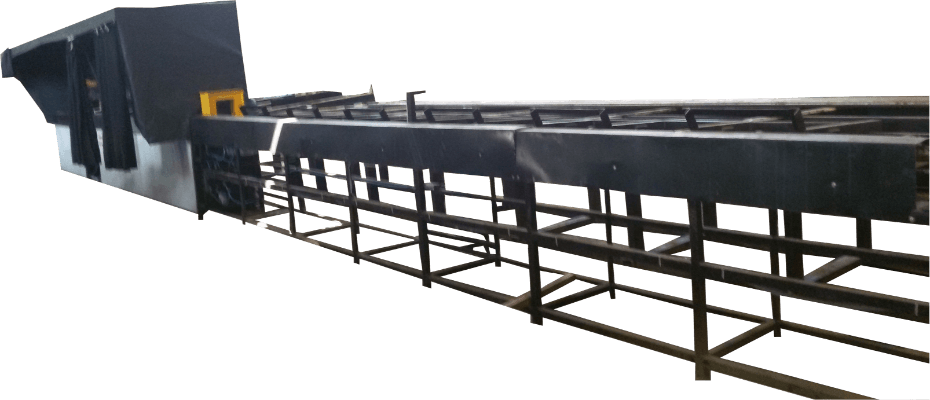

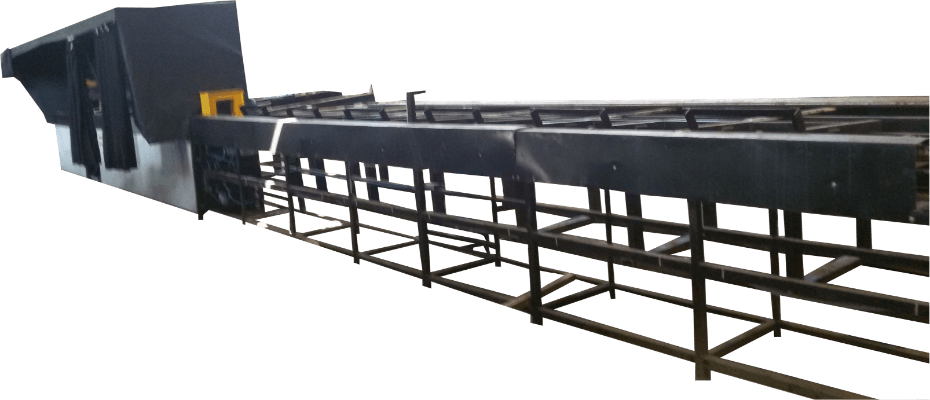

Mobile Current Generators

Our mobile current generators are ideal for conducting magnetic particle inspections on large and exceptionally heavy parts. They are well-suited for testing parts that cannot be loaded onto a stationary machine. These units come equipped with both AC and Half Wave DC output capabilities.