Your global service supplier for Non destructive testing

Impac Labs, a global leader in Non-destructive testing, pioneers the realm of differential Flux Analysis. With unrivaled expertise, we provide cutting-edge solutions to industries worldwide. Trust us to safeguard your assets through precision and innovation.

DFA

(DIFFERENTIAL FLUX ANALYSIS)

Impac Labs, a global leader in Non-destructive testing, pioneers the realm of differential Flux Analysis. With unrivaled expertise, we provide cutting-edge solutions to industries worldwide. Trust us to safeguard your assets through precision and innovation.

Innovating Today for a Smarter Tomorrow

(DIFFERENTIAL FLUX ANALYSIS)

DFA

Our Expertise

We excel in design of eddy current testing systems used for Non-Destructive testing of metals & their parts. Eddy currents can detect abnormalities in materials & defects close to the surface. Our systems are modular, designed for industrial use & deploy advanced software to perform testing with high reliability. Our latest technology is DFA. The specialty of DFA is lift-off compensation to compensate for small gaps between the probe & test object.

Brief Description of DFA

DFA stands for Differential Flux Analysis. It is our Patented and German based sensor technology for fast quality inspection of Metallic parts.

DFA is automatable, easy to integrate in manufacturing and does not impact cycle times.

DFA is easy to train to the operators.

DFA is a non-destructive testing for ferrous and non-ferrous parts.

DFA is quick and sustainable solution to increase quality in manufacturing.

DFA enables 100% in-process inspection.

Our Technologies

Lorem ipsum dolor sit amet

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Our Technologies

DFA

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nulla tortor augue, pulvinar vel dignissim at, gravida non magna. Maecenas lacinia, dolor hendrerit placerat vulputate, lectus nisi facilisis massa, eu semper sapien mauris vel ligula. Pellentesque mollis ante est, in blandit justo porttitor quis.

Eddy

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nulla tortor augue, pulvinar vel dignissim at, gravida non magna. Maecenas lacinia, dolor hendrerit placerat vulputate, lectus nisi facilisis massa, eu semper sapien mauris vel ligula. Pellentesque mollis ante est, in blandit justo porttitor quis.

DFA

Desktop Eddy

Single Channel Eddy

Multi Channel Eddy

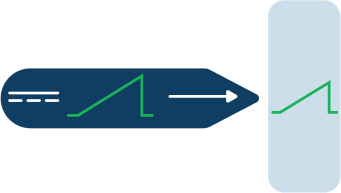

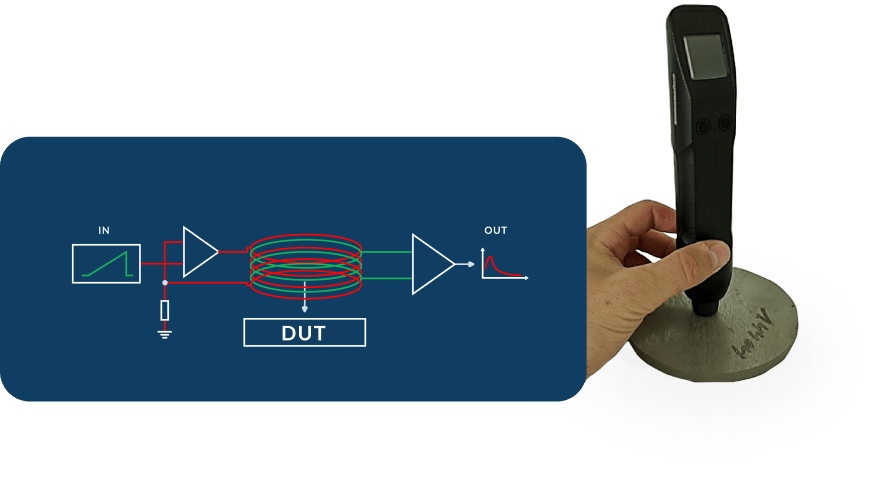

Excitation with a ramp-shaped electromagnetic signal

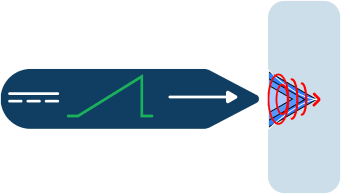

Formation of eddy currents in the sample

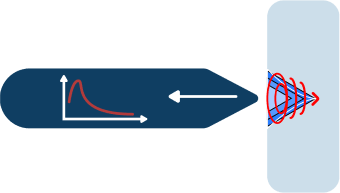

The sensor measures the voltage-time curve of the emitted field – the inductive fingerprint

What is the invention behind DFA?

DFA compensates unwanted external effects (like distance and orientation) on ferrous and non-ferrous parts and allows a repeatable and process stable measurement.

DFA’s compensation is based on the combination of a hardware-controlled lift-off of and a pulsed-ramped-linear current excitation.

Advantages of DFA over Conventional Solutions

Conventional Solutions

- One specially designed coil per application

- Measurement result represents the average value

- Not Portable

- OK part always to be present for comparison with the sample

- Testing of components at PPAP stage not possible

DFA

- No special coil required. One sensor head for various applications.

- Point /line measurement possible resulting in pointed values at the desired area

- Portable version available

- OK parts can be calibrated and its data can be stored in the system

- Easy testing of components during PPAP with DFA Lab equipment

What Our Client's are Saying

Impac Labs’ DFA has completely transformed our research process. The precision and accuracy of the results have streamlined our workflow, saving time and resources. It's a must-have for any lab seeking reliable data.

The Eddy from Impac Labs has improved our defect detection capabilities significantly. It delivers fast, precise results and requires minimal maintenance. This machine has streamlined our operations, ensuring higher safety standards and product quality. We couldn’t be more satisfied with its performance!