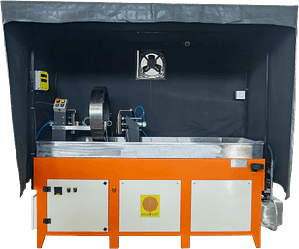

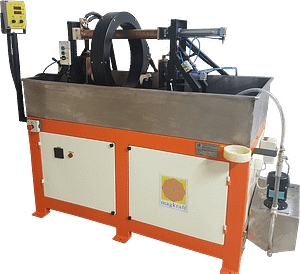

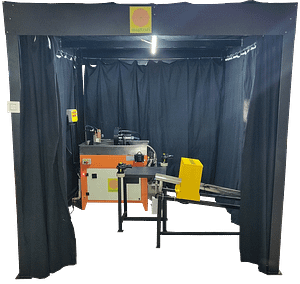

PLC Controlled MPI Machine

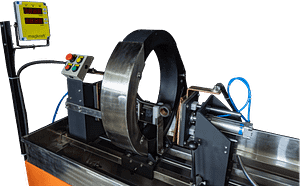

Our PLC-based MPI test bench units go a step ahead of conventional machines for MPI inspection. They are used across a wide range of industries, such as aerospace, marine automotive, oilfield equipment & railways, for the detection of surface & subsurface defects. These benches are two vector machines. A circular magnetic field is generated by clamping the part between the headstock & tailstock & passing a current through the part. Parts with a central bore can be tested using the threaded bar method. A longitudinal magnetic field is generated changeover is accomplished by solid-state circuitry.

Features

- PLC-Based Control. Automatic Cycle for faster testing.

- 7 Inch Touch Screen for control & display.

- Operator controlled an automatic double shot.

- 50 Program memory to store settings for different parts.

- Error displayed on a touch screen for easy diagnostics.

- Independent current control for Circular and longitudinal magnetization.

- Independent transformers for Circular and longitudinal magnetization, thereby avoiding the use of noisy changeover switches.

- Digital, stepless current control.

- Heavy-duty transformers. No need to wait between two shots.

- Both sides have Pneumatic clamping.

- Stainless Steel liquid storage tank.

- Stainless Steel collection tray

- Reverse agitation bath system.

- AC to DC changeover for headshot uses solid-state circuitry.

- Continuously movable tailstock with cam lock

- Steady Rollers for job placement

- Integrated decaying-AC demagnetization with automatic control

- Feedback loop-based current control with current failure indicator.

- Standard make PLC & HMI.

- Easily serviceable.

Specifications

| Headshot Current Capacity | Models starting from 2000A going up to 6000A |

| Maximum Part Length Accommodation | Starting from 600mm going up to 1500mm |

| Maximum Part Diameter | Starting from 100mm going up to 300mm |

| Maximum Part Weight | 300Kg |

| Storage Bath Capacity | 25 L |

| Shot Time | Adjustable from 0.5 sec 2.0 sec |

| Power Supply | 3 Phase 3 Wire 415V AC/220V AC |

| Frequency | 50Hz or 60Hz |

| Pneumatic Pressure Required | 4-6 Kg/cm2 |

| Coil Diameters | 300mm, 400mm, 500mm |

| Control Voltage | 24V DC |

| Touch Screen Display Size | 7” Diagonal |

- Benefits

- SCR-based digital current control for accuracy & precision

- Feedback loop ensures repeatability

- Reverse agitation system keeps the powder always dissolved in the carrier fluid.

- Pneumatic clamping ensures no sparks

- 7-inch Touch Screen for operator comfort.

- PLC-controlled operation for faster & reliable testing

- No changeover sound

- Low voltage output for operator safety

- Operator controlled the Poka yoke for the demagnetization cycle.

- applications

- Magnetic particle inspection of automotive parts such as shafts, axles, connecting rods, hubs, couplings, steering parts, gears, etc.

- Fasteners

- Railway parts

- Sample testing in the steel industry

- Ferrous raw material testing in all industries

- Oil field equipment parts

Product models

Horizontal Clamping Models

| Model | Head Shot Capacity | Coil Shot Capacity | Coil Inside Diameter | Maximum Part Length | Maximum Part Diameter |

| MK-20-C-60-A | 2000A AC & HWDC | 7.5 KAT AC | 300mm | 600mm | 100mm |

| MK-20-C-120-A | 2000A AC & HWDC | 7.5 KAT AC | 300mm | 1200mm | 100mm |

| MK-30-C-60-A | 3000A AC & HWDC | 10.0 KAT AC | 300mm | 600mm | 150mm |

| MK-30-C-120-A | 3000A AC & HWDC | 10.0 KAT AC | 300mm | 1200mm | 150mm |

| MK-40-C-100-A | 4000A AC & HWDC | 10.0 KAT AC | 400mm | 1000mm | 200mm |

| MK-40-C-150-A | 4000A AC & HWDC | 10.0 KAT AC | 400mm | 1500mm | 200mm |

| MK-50-C-100-A | 5000A AC & HWDC | 10.0 KAT AC | 400mm | 1000mm | 250mm |

| MK-50-C-150-A | 5000A AC & HWDC | 10.0 KAT AC | 400mm | 1500mm | 250mm |

| MK-60-C-100-A | 6000A AC & HWDC | 10.0 KAT AC | 500mm | 1000mm | 300mm |

| MK-60-C-150-A | 6000A AC & HWDC | 10.0 KAT AC | 500mm | 1500mm | 300mm |

Vertical Clamping Models

| Model | Head Shot Capacity | Coil Shot Capacity | Coil Inside Diameter | Maximum Part Length | Maximum Part Diameter |

| MK-20-C-20-V-A | 2000A AC & HWDC | 7.5 KAT AC | 200mm | 200mm | 100mm |

| MK-20-C-30-V-A | 2000A AC & HWDC | 7.5 KAT AC | 300mm | 300mm | 100mm |

| MK-60-BG (For Bull Gears) | 6000A HWDC | 10.0 KAT AC | 450mm | 100mm | 400mm |