Magnetic Particle Inspection of Connecting Rods

The connecting rod is a crucial component in an automobile engine, acting as a linkage between the piston and the crankshaft. Its primary role involves converting the reciprocating motion of the piston into the rotational motion of the crankshaft, a vital process that allows the engine to efficiently generate power. Enduring significant forces and stresses during each combustion cycle, the connecting rod plays a pivotal role in the engine's operation. Any failure in the connecting rod could lead to severe engine damage with potentially catastrophic consequences.

Magnetic Particle Testing (MPT) plays a critical role in ensuring the reliability and safety of connecting rods. This non-destructive testing method involves applying a magnetic field and iron particles to the surface of the rod. By doing so, it helps identify minute cracks, defects, and flaws that may be invisible to the naked eye. The detection of such imperfections is crucial, as they have the potential to result in catastrophic engine failure if left undetected. MPT significantly enhances the quality control process during manufacturing and proves invaluable in routine maintenance, preventing potential accidents, breakdowns, and ensuring the long-term performance and durability of the engine.

The connecting shaft needs to be magnetized in two directions perpendicular to each other. A circular magnetic field is used to detect longitudinal flaws in the part.

Circular magnetic field is generated by passing a current through the length of the connecting rod.

Calculation of head shot current is done as per the formula given in ASTM standards.

Head Shot Current = 20 X Diameter (mm)

In the above formula, the diameter should be taken as the maximum diameter of the connecting rod.

Longitudinal magnetic field, required for detection of transverse defects is generated by using an encircling coil.

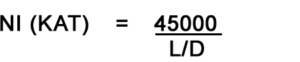

Formula for calculation of coil current

In the above formula, the diameter should be taken as the average diameter of the connecting rod.

![]()

A horizontal bench-type machine is employed for conducting magnetic particle testing on connecting rods. The connecting rod is positioned on the stable rollers installed on the head and tailstock of the machine. An arrangement operated pneumatically is utilized to secure the connecting rod from both ends. Pneumatic clamping guarantees the absence of sparking when a high current is applied to the connecting rod. The utilization of braided copper pads is also advised to mitigate arcing sparks.

Conventional Technique

A two vector PLC based bench type magnetic crack detector machine is used to perform testing on the connecting rods.

- Ensure the connecting rod’s surface is cleaned and dry before inspection.

- Position the connecting rod on the fixture.

- Apply a magnetic solution bath to the connecting rod.

- Initiate the testing procedure by pressing the ‘Cycle Start’ button.

- The connecting rod automatically gets clamped.

- Halt the flow of the bath.

- Allow the current to pass through the connecting rod.

- Observe the results on the digital metering unit.

- The connecting rod automatically gets de-clamped.

- Inspect the connecting rod under UV light for longitudinal defects. Rotate it on steady rollers for a comprehensive examination.

- Apply the bath to the job once again.

- Press the ‘Cycle Start’ button.

- Stop the flow of the bath.

- Allow the current to pass through the coil.

- Observe the results on the digital metering unit.

- Inspect the connecting rod under UV light for transverse defects. Rotate it on rollers for a comprehensive examination.

Multidirectional Technique

- Ensure the connecting rod’s surface is cleaned and dry before inspection.

- Position the connecting rod on the steady rollers.

- Apply a bath to the connecting rod.

- Initiate the testing procedure by pressing the ‘Cycle Start’ button.

- The connecting rod will automatically be clamped in place.

- Halt the bath flow.

- Allow the current to pass through the connecting rod and the coil in multidirectional mode.

- Observe the results on the digital metering unit.

- The connecting rod will be automatically de-clamped.

- Inspect the connecting rod under UV light for defects in all directions. Rotate it on rollers for a comprehensive examination.

- Conclude the testing process with demagnetization.