Magnetic Particle Inspection of Cam shafts

A camshaft is a crucial element within an internal combustion engine, tasked with regulating the opening and closing of the engine's intake and exhaust valves. It incorporates specially crafted lobes or "cams" that exert pressure on valve lifters, initiating the movement of the valves. This precisely coordinated valve operation ensures the optimal intake of fuel-air mixture and the expulsion of exhaust gases, thereby influencing overall engine performance.

In the manufacturing and maintenance of camshafts, Magnetic Particle Testing (MPT) plays a pivotal role. MPT is a non-destructive testing method designed to identify surface and near-surface flaws, cracks, or defects by employing magnetic particles. This process involves magnetizing the camshaft and applying fine iron particles, which accumulate at potential defect locations, making them visible. Detecting imperfections early through MPT enhances the reliability, durability, and safety of camshafts—components critical to the seamless operation of an engine. The meticulous nature of this testing procedure emphasizes the importance of upholding the highest standards in automotive engineering and performance.

The camshaft requires magnetization in two directions perpendicular to each other to facilitate comprehensive testing. A circular magnetic field is employed to identify longitudinal flaws in the component.

The generation of the circular magnetic field involves passing a current through the length of the camshaft. The calculation of the headshot current is determined using the formula outlined in ASTM standards:

Head Shot Current = 20 X Diameter(mm)

In this formula, the diameter is considered as the diameter of the shaft portion. For the detection of transverse defects, a longitudinal magnetic field is essential, and this is achieved by utilizing an encircling coil.

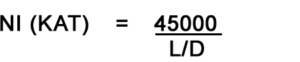

Formula for calculation of coil current

In the above formula, the diameter should be taken as the average diameter of the cam shaft. The average diameter can be calculated by the following formula.

In the magnetic particle testing process for camshafts, a horizontal bench-type machine is employed. The camshaft is positioned on stable rollers attached to both the head and tailstock of the machine. To secure the camshaft in place, a pneumatically operated arrangement is utilized, clamping it from both ends. This pneumatic clamping mechanism is crucial to prevent sparking when a high current is passed through the camshaft.

Additionally, the recommendation includes the use of braided copper pads to further enhance safety by eliminating arcing sparks during the testing procedure. This meticulous approach to clamping and safety measures underscores the importance of precision and caution in magnetic particle testing for camshafts.

Conventional Technique

A two vector PLC based bench type magnetic crack detector machine is used to perform testing on the cam shafts.

- Begin by cleaning and thoroughly drying the surface of the camshaft before inspection.

- Position the camshaft securely on the steady rollers.

- Apply the magnetic solution bath to the camshaft.

- Initiate the testing sequence by pressing the ‘Cycle Start’ button.

- The camshaft will automatically clamp into position.

- Pause the flow of the bath.

- Allow the current to pass through the camshaft, and observe the readings on the digital metering unit.

- Automatically release the clamped camshaft.

- Inspect the camshaft under UV light for longitudinal defects, rotating it on steady rollers.

- Apply the bath once again.

- Press the ‘Cycle Start’ button.

- Pause the flow of the bath.

- Now, allow the current to pass through the coil, and observe the readings on the digital metering unit.

- Inspect the camshaft under UV light for transverse defects, rotating it on rollers.

- Conclude the process with demagnetization.

Multidirectional Technique

In this custom-built machine, pneumatic actuators automatically reposition the coil. Given the short length of the housing, the coil is shifted aside to ease the loading of the part.

- Ensure the camshaft’s surface is cleaned and dry before inspection.

- Position the camshaft on the steady rollers.

- Apply a bath to the camshaft.

- Initiate the testing process by pressing the ‘Cycle Start’ button.

- The camshaft will automatically be clamped, and the coil will align itself.

- Pause the bath flow.

- Now, allow the current to pass through the camshaft and coil in multidirectional mode.

- Results will be displayed on the digital metering unit.

- The camshaft will automatically be released from the clamped position.

- Inspect the camshaft under UV light for defects in all directions while rotating on rollers.

- Conclude the process with demagnetization.