Technologies

Eddy Current Application Data

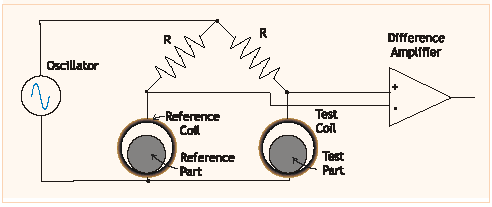

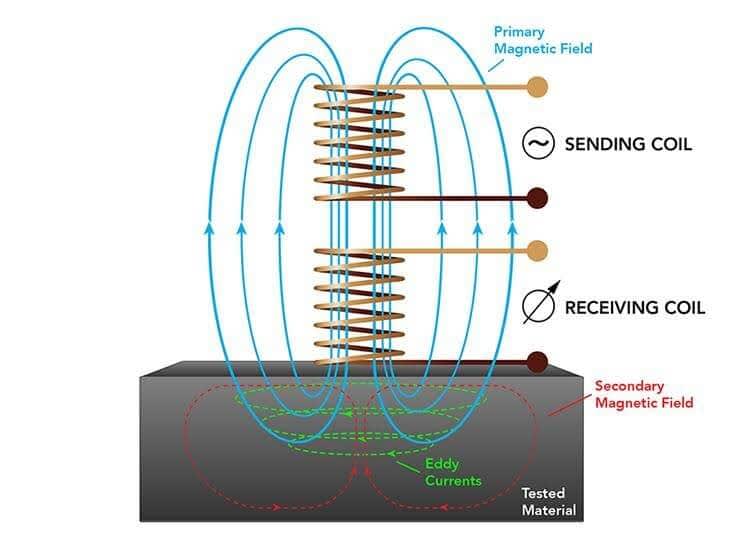

Eddy currents are electrical currents induced in a conductor by a time-varying magnetic field. Eddy currents flow in a circular pattern, but their paths are oriented perpendicular to the direction of the magnetic field. Fig1

Eddy Current Dependency

Eddy currents propagation in conductor depends on Permeability, Conductivity, Geometry, Temperature and frequency applied. These properties also decide the application of Eddy Current in Industrial Purposes.

Applications of Eddy Currents

Eddy Current Applications

- Conductivity measurement

- Sorting

3. Defect detection

4. Coating Thickness Measurement

Conductivity Measurement

The distribution and intensity of eddy currents in non-ferromagnetic materials is strongly affected by electrical conductivity. In a material of relatively high conductivity, strong eddy currents are generated at the surface. In turn, the strong eddy currents form a strong secondary electromagnetic field opposing the applied primary field. As a result, the strength of the primary field decreases rapidly with increasing depth below the surface. In poorly conductive materials, the primary field generates small amounts of eddy currents, which produce a small opposing secondary field. Therefore, in highly conductive materials, strong eddy currents are formed near the surface, but their strength reduces rapidly with depth. In poorly conductive materials, weaker eddy currents are generated near the surface, but they penetrate to greater depths. So Eddy currents systems can be used for Conductivity measurements. These systems are calibrated on copper Sheet sample of 100% IACS (International Annealed Copper Standards).

Sorting

Heat treating (or age hardening) a metal changes its hardness and its electrical conductivity. The same variables of chemical composition, heat treatment, and metal working that determine the mechanical properties of a metal, also establish its electrical conductivity and magnetic permeability. As a result, correlation has been obtained between electrical conductivity and mechanical properties.

This correlation does not mean the conductivity value of a metal will reliably measure its mechanical properties. However, for some metals, change of the measured conductivity from a specified conductivity range or excessive variation in conductivity within a given part or specimen indicates a probable change in properties. The correlation of conductivity measurement with mechanical properties requires a clearly defined change in conductivity between the various alloys, tempers, or heat treatments involved. Differences in conductivity and/or permeability exist between alloys of many metals including aluminium, copper, magnesium, steel, and titanium. Not all alloys in each system are separable because of overlapping conductivity ranges. If one material has a relatively high conductivity and the other is relatively low within the given range, material separation is possible.

Based on the above data, material sorting can be applied to various alloys. Some examples being :

- Sorting of bars or components according to alloy type.

- Sorting of fasteners according to hardness.

- Segregation of forgings as per heat treatment condition.

- Evaluation of Gudgeon pins for case-depth.

Defect Detection

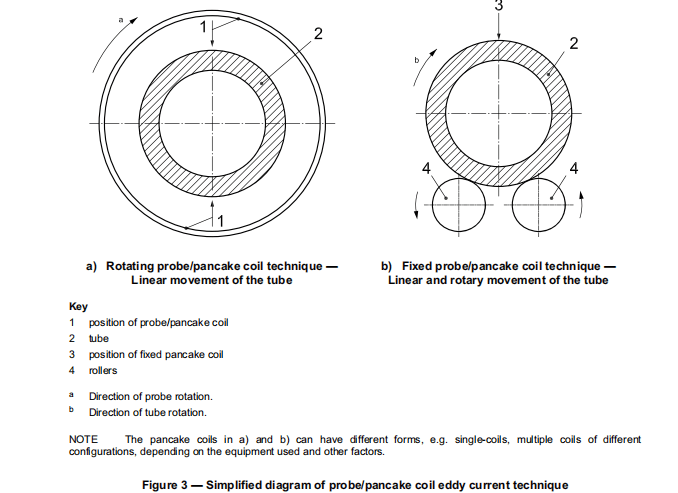

- Rotating Technique

- Component Rotating Technique

- Probe Rotating Technique

- Stationary coil technique

- Full body Encircling

- Segment Coil

- Bobbin Type/ID cracks detection

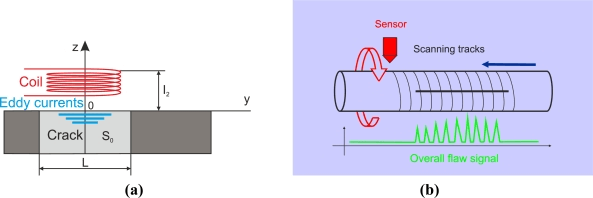

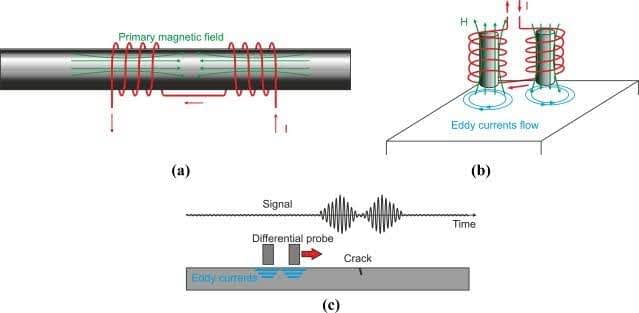

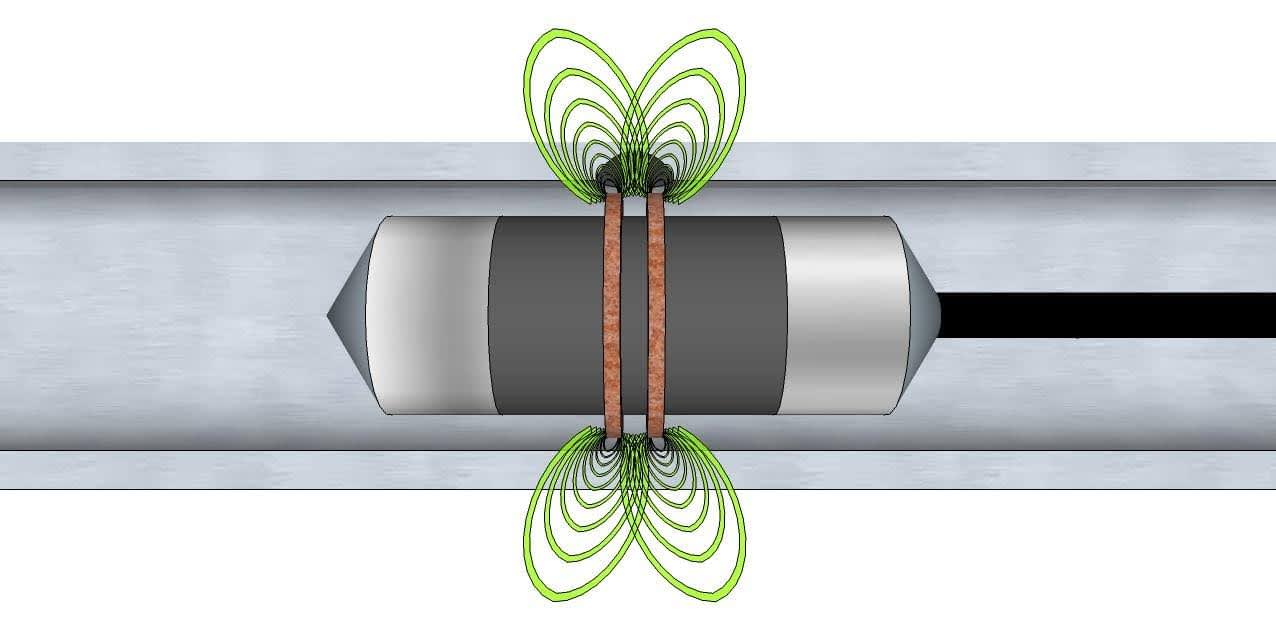

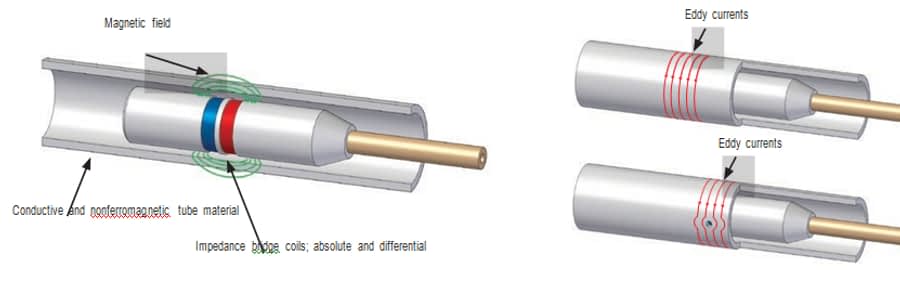

All three types Full body/Encircling, Segment and Bobbin/ID type technique is used to detect discontinuities in parts that are conductors of electricity(Mostly used for Tubes, Bars & Wire Rods). An eddy current is a circulating electrical current induced in a conductor by an alternating magnetic field.

An eddy current instrument generates an alternating current that is designed to go through a coil of copper wire that has been placed in a holder called a ”probe or coil”, this results in the coil producing an alternating magnetic field that when placed near a conductor, generates electrical currents within the conductor. When these eddy currents encounter an obstacle such as a crack, the normal path and strength of the currents is changed and this change is detected, processed and then displayed on the instrument display.

Coating Thickness Measurement

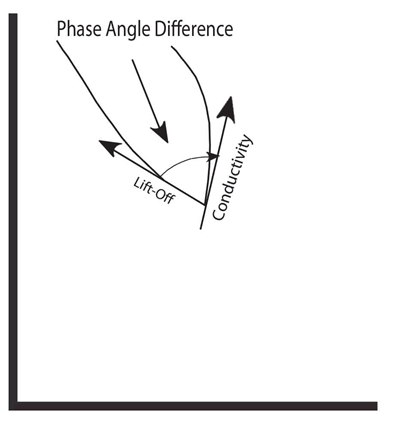

Changes in conductivity and lift-off are said to have different phase angles. This phase angle difference is further illustrated in Figure below. The lift-off curve can also be used to measure the thickness of non-conductive coatings on a conductive surface. This is done by comparing the length of lift-off line for an unknown coating thickness to the lengths of lift-off lines for known thickness.

The distribution and intensity of eddy currents in non-ferromagnetic materials is strongly affected by electrical conductivity. In a material of relatively high conductivity, strong eddy currents are generated at the surface. In turn, the strong eddy currents form a strong secondary electromagnetic field opposing the applied primary field. As a result, the strength of the primary field decreases rapidly with increasing depth below the surface. In poorly conductive materials, the primary field generates small amounts of eddy currents, which produce a small opposing secondary field. Therefore, in highly conductive materials, strong eddy currents are formed near the surface, but their strength reduces rapidly with depth. In poorly conductive materials, weaker eddy currents are generated near the surface, but they penetrate to greater depths. So Eddy currents systems can be used for Conductivity measurements. These systems are calibrated on copper Sheet sample of 100% IACS (International Annealed Copper Standards).

Heat treating (or age hardening) a metal changes its hardness and its electrical conductivity. The same variables of chemical composition, heat treatment, and metal working that determine the mechanical properties of a metal, also establish its electrical conductivity and magnetic permeability. As a result, correlation has been obtained between electrical conductivity and mechanical properties.

This correlation does not mean the conductivity value of a metal will reliably measure its mechanical properties. However, for some metals, change of the measured conductivity from a specified conductivity range or excessive variation in conductivity within a given part or specimen indicates a probable change in properties. The correlation of conductivity measurement with mechanical properties requires a clearly defined change in conductivity between the various alloys, tempers, or heat treatments involved. Differences in conductivity and/or permeability exist between alloys of many metals including aluminium, copper, magnesium, steel, and titanium. Not all alloys in each system are separable because of overlapping conductivity ranges. If one material has a relatively high conductivity and the other is relatively low within the given range, material separation is possible.

Based on the above data, material sorting can be applied to various alloys. Some examples being :

- Sorting of bars or components according to alloy type.

- Sorting of fasteners according to hardness.

- Segregation of forgings as per heat treatment condition.

- Evaluation of Gudgeon pins for case-depth.

- Rotating Technique

- Component Rotating Technique

- Probe Rotating Technique

- Stationary coil technique

- Full body Encircling

- Segment Coil

- Bobbin Type/ID cracks detection

All three types Full body/Encircling, Segment and Bobbin/ID type technique is used to detect discontinuities in parts that are conductors of electricity(Mostly used for Tubes, Bars & Wire Rods). An eddy current is a circulating electrical current induced in a conductor by an alternating magnetic field.

An eddy current instrument generates an alternating current that is designed to go through a coil of copper wire that has been placed in a holder called a ”probe or coil”, this results in the coil producing an alternating magnetic field that when placed near a conductor, generates electrical currents within the conductor. When these eddy currents encounter an obstacle such as a crack, the normal path and strength of the currents is changed and this change is detected, processed and then displayed on the instrument display.

Changes in conductivity and lift-off are said to have different phase angles. This phase angle difference is further illustrated in Figure below. The lift-off curve can also be used to measure the thickness of non-conductive coatings on a conductive surface. This is done by comparing the length of lift-off line for an unknown coating thickness to the lengths of lift-off lines for known thickness.