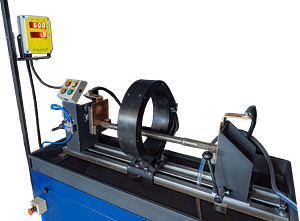

Standard MPI Machine

Our standard MPI test bench units establish a benchmark for MPI inspection, finding applications across diverse industries, including automotive, fasteners, hand tools, oil field equipment, railways, and education & training for the detection of surface & subsurface defects. These benches, functioning as two vector machines, create a circular magnetic field by clamping the part between the headstock and tailstock and passing a current through it. The threaded bar method allows the testing of parts with a central bore. Additionally, a longitudinal magnetic field is generated through the use of an encircling coil.

- Designed for light to moderate production loads.

- A magnetization time of 1.0 second facilitates the comprehensive development of indications.

- Offered in a variety of amperages, part lengths, and coil diameters.

- Every model comes equipped with a dark room featuring a ventilation fan and white light, specifically designed for testing with fluorescent powders.

Features

- Independent current control for Circular and longitudinal magnetization.

- Separate transformers for Circular and longitudinal magnetization, eliminating the need for noisy changeover switches.

- Digital, stepless current control.

- Two large digital readout ampere meters with retention. Pneumatic clamping.

- Stainless Steel liquid storage tank.

- Reverse agitation bath system.

- AC/HWDC changeover for headshot.

- Continuously movable tailstock with cam lock.

- V Blocks for job placement.

- Integrated decaying-AC demagnetization with automatic control.

- Feedback loop-based current control with current failure indicator.

- Minimal electronic components for easy serviceability.

Specifications

| Headshot Current Capacity | Models staring from 1500A going up to 4000A |

| Maximum Part Length Accommodation | Starting from 400mm going up to 1200mm |

| Maximum Part Diameter | Staring from 75mm going up to 200mm |

| Maximum Part Weight | 150Kg |

| Storage Bath Capacity | 25 L |

| Shot Time | 1.0 Seconds |

| Power Supply | 3 Phase 4 Wire 415V AC/220V AC |

| Frequency | 50Hz or 60Hz |

| Pneumatic Pressure Required | 4-6 Kg/cm2 |

| Coil Diameters | 200mm, 300mm, 450mm |

| Control Voltage | 24V DC |

- Benefits

- Utilizes SCR-based digital current control for enhanced accuracy and precision.

- Implements a feedback loop to ensure repeatability.

- Incorporates a reverse agitation system to maintain constant powder dissolution in the carrier fluid.

- Employs pneumatic clamping to ensure spark-free operations.

- Features a large, easy-to-read digital display for operator comfort.

- Operates without changeover sound.

- Provides low voltage output for operator safety.

- Cost-effective solution.

- applications

- Conducts magnetic particle inspection on automotive parts such as shafts, axles, connecting rods, hubs, couplings, steering parts, etc.

- Performs sample testing in the steel industry.

- Facilitates ferrous raw material testing in all industries.

- Inspects oil field equipment parts.

- Examines railway parts.

- Supports education and training initiatives.

Product models

Horizontal Clamping Models

| Model | Head Shot Capacity | Coil Shot Capacity | Coil Inside Diameter | Maximum Part Length | Maximum Part Diameter |

| MK-15-C-40-S | 1500A AC & HWDC | 7.5 KAT AC | 200mm | 400mm | 75mm |

| MK-20-C-60-S | 2000A AC & HWDC | 7.5 KAT AC | 300mm | 600mm | 100mm |

| MK-20-C-120-S | 2000A AC & HWDC | 7.5 KAT AC | 300mm | 1200mm | 100mm |

| MK-30-C-60-S | 3000A AC & HWDC | 10.0 KAT AC | 300mm | 600mm | 150mm |

| MK-30-C-120-S | 3000A AC & HWDC | 10.0 KAT AC | 300mm | 1200mm | 150mm |

| MK-40-C-120-S | 4000A AC & HWDC | 10.0 KAT AC | 450mm | 1200mm | 200mm |