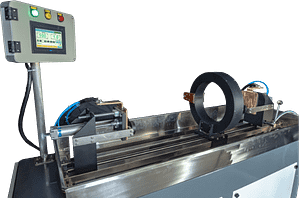

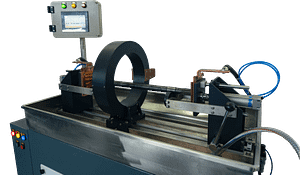

Multi-directional Bench Type Magnetic Particle Testing Machine

This machine employs multi-directional magnetization to identify defects in all orientations in a single shot. This approach differs from the combined magnetization shot used in conventional machines, which does not comply with ASTM standards. The multi-directional magnetization is achieved by combining two vectors: one generated by passing current through the job, and the other by one or more encircling coils.

In the current competitive marketplace, the integrity and reliability of products are of utmost importance. Magnetic Particle Testing, when carried out by an impartial third party, stands as a reliable method to:

- This machine is capable of detecting both longitudinal and transverse cracks in a single shot.

- The headshot and coil current can be individually switched between HWDC and AC for detecting subsurface and surface cracks. The changeover from AC to DC is accomplished through solid-state circuitry.

- The machine features an adjustable magnetization time of up to 2.0 seconds, enabling the thorough development of indications.

- Available in a range of amperages, part lengths, and coil diameters.

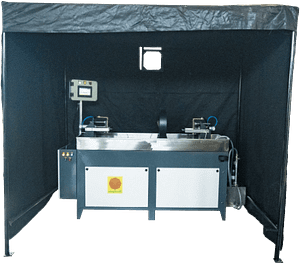

- All models include a dark room with a ventilation fan and white light for testing with fluorescent powders.

Features

- PLC-Based Control for efficient testing cycles.

- 7-inch Touch Screen for intuitive control and display.

- Operator-controlled automatic double shot.

- Storage capacity of 1000 programs to accommodate various part settings.

- Automatic Parts Counter for streamlined operations.

- Independent current control for Circular and longitudinal magnetization.

- Separate transformers for Circular and longitudinal magnetization, eliminating the need for noisy changeover switches.

- Digital, stepless current control for precise adjustments.

- Heavy-duty transformers with no waiting time between two shots.

- Pneumatic clamping on both sides for secure positioning.

- Stainless Steel liquid storage tank for durability.

- Stainless Steel collection tray for efficient fluid management.

- Reverse agitation bath system for effective material processing.

- Solid-state circuitry for AC to DC changeover.

- Continuously movable tailstock with cam lock for flexibility.

- Steady Rollers for precise job placement.

- Integrated decaying-AC demagnetization with automatic control.

- Feedback loop-based current control with a failure indicator for enhanced monitoring.

- Standard make PLC & HMI, designed for easy serviceability.

Specifications

| Headshot Current Capacity | Models starting from 1000A going up to 5000A |

| Maximum Part Length Accommodation | Starting from 200mm going up to 1600mm |

| Maximum Part Diameter | Starting from 100mm going up to 250mm |

| Maximum Part Weight | 450Kg |

| Storage Bath Capacity | 25 L |

| Shot Time | Adjustable from 0.5 sec 2.0 sec |

| Power Supply | 3 Phase 3 Wire 415V AC/220V AC |

| Frequency | 50Hz or 60Hz |

| Pneumatic Pressure Required | 4-6 Kg/cm2 |

| Coil Diameters | 200mm, 300mm, 400mm, 450mm, 500mm |

| Control Voltage | 24V DC |

| Touch Screen Display Size | 7” Diagonal |

Optional features:

- Separate Digital Ammeters for precise current monitoring.

- Mag-shot-activating front push bar with 1-touch control to enable/disable this feature.

- Database System with an advanced touch screen operating interface and barcode scanner, eliminating the need for manual inputs.

- User-controlled security systems with password protection, supervisor locks, and customizable operator access profiles.

- Daily reminder alarms to verify UV light, visible light, and particle bath concentration for process control requirements.

- Error displayed on the touch screen for easy diagnostics.

- Benefits

- Reduces the time required to test a part by half compared to conventional machines, as the part is checked in a single shot for both longitudinal and transverse defects.

- Significant space and manpower savings by half for high production rates.

- SCR-based digital current control for accuracy and precision.

- Feedback loop ensures repeatability.

- Reverse agitation system keeps the powder continuously dissolved in the carrier fluid.

- Pneumatic clamping ensures spark-free operation.

- 7-inch Touch Screen for operator comfort.

- PLC-controlled operation for faster and reliable testing.

- No changeover sound during operation.

- Low voltage output prioritizes operator safety.

- Operator-controlled Poka yoke for the demagnetization cycle.

- applications

- Automotive Parts

- Shafts

- Axles

- Connecting rods

- Hubs

- Couplings

- Steering parts

- Gears

- Fasteners

Product models

Horizontal Clamping Models

| Model | Head Shot Capacity | Coil Shot Capacity | Coil Inside Diameter | Maximum Part Length | Maximum Part Diameter |

| MK-20-C-20-MD | 2000A AC & HWDC | 7.5 KAT AC | 200mm | 200mm | 100mm |

| MK-20-C-30-MD | 2000A AC & HWDC | 7.5 KAT AC | 300mm | 300mm | 100mm |

| MK-30-C-30-MD | 3000A AC & HWDC | 10.0 KAT AC | 300mm | 300mm | 150mm |

| MK-30-C-45-MD | 3000A AC & HWDC | 10.0 KAT AC | 450mm | 450mm | 150mm |

| MK-40-2C-90-MD | 4000A AC & HWDC | 2 Coils 8.0 KAT AC each | 450mm | 900mm | 200mm |

| MK-40-4C-160-MD | 4000A AC & HWDC | 4 Coils 7.5 KAT AC each | 400mm | 1600mm | 200mm |

| MK-50-2C-90-MD | 5000A AC & HWDC | 2 Coils 8.0 KAT AC each | 450mm | 900mm | 250mm |

| MK-50-4C-160-MD | 5000A AC & HWDC | 4 Coils 7.5 KAT AC each | 400mm | 1600mm | 250mm |

Vertical Clamping Models

| Model | Head Shot Capacity | Coil Shot Capacity | Coil Inside Diameter | Maximum Part Length | Maximum Part Diameter |

| MK-20-C-20-V-MD | 2000A AC & HWDC | 7.5 KAT AC | 200mm | 200mm | 100mm |

| MK-20-C-30-V-MD | 2000A AC & HWDC | 7.5 KAT AC | 300mm | 300mm | 100mm |