Eddy Current Testing Systems

Eddy Current Testing: Unmatched Precision in Non-Destructive Testing

Eddy Current Testing (ECT) stands out as a non-destructive testing method employing electromagnetic induction to identify cracks, corrosion, and other flaws in conductive materials. Widely applied in diverse industries, such as aerospace, automotive, and manufacturing, ECT is a versatile technique. At Compac Technologies, we leverage cutting-edge ECT methods to deliver dependable and highly sensitive inspections customized to your unique requirements.

Challenges in Eddy Current Testing

- Material Complexity: Varied materials and intricate geometries necessitate tailored testing approaches.

- Sensitivity and Depth Penetration: Striking the appropriate balance between sensitivity and penetration depth poses a challenge.

- Conductivity Variations: Fluctuations in material conductivity can impact test results.

Solutions We Offer

- Adaptable Testing Protocols: Leveraging our ECT expertise, we can tailor testing procedures to suit diverse materials and shapes.

- Advanced Technology: Employing the latest ECT equipment to guarantee precise and consistent results.

- Experienced Technicians: Our team of seasoned experts ensures accurate interpretation of test results.

Our Methodology for Eddy Current

- Pre-inspection Consultation: Evaluate client needs and define the testing scope, selecting the appropriate method based on materials and potential flaws.

- Calibration and Standardization: Utilize certified reference samples to calibrate the ECT system for precise measurements.

- Testing Parameter Optimization: Adjust the frequency, gain, and other parameters to suit the specific part being inspected.

- Automated or Manual Scanning: Depending on requirements, employ automated scanning or manual hand probes to inspect the material.

- Real-Time Data Analysis: Analyze signals during inspection to identify flaws or material changes.

- Detailed Reporting: Compile results into an easy-to-understand report, including insights and recommendations.

- Post-Inspection Support: Provide ongoing support to clients with additional analyses or any queries related to the inspection.

Compac Technologies is dedicated to achieving excellence in Eddy Current Testing, guaranteeing that your parts and components are devoid of defects that might jeopardize performance or safety. Our specialized approach and cutting-edge technology instill confidence in your manufacturing or operational activities. Reach out to us today to discover how our ECT services can offer precise and trustworthy inspections crucial to the success of your industry.

Instruments

Our Eddy Current Instruments leverage the most advanced technology in eddy current testing, enabling precise identification and sorting of materials based on their hardness and material properties.

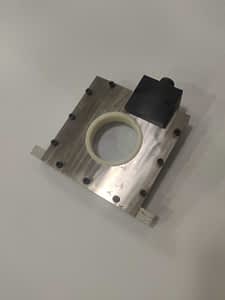

Automatic Systems

Leveraging on our expertise in eddy current testing methodology and machine design, we specialize in developing advanced automatic material sorting systems that utilize eddy current techniques.