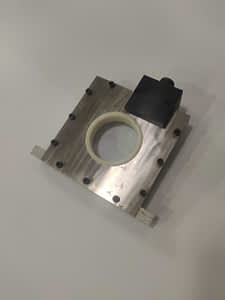

Eddy Current Testing machine Instrument

Eddy current testing is based on the scientific principle of electromagnetic induction. In this method, an alternating current flows through a coiled wire within an eddy current probe, creating a fluctuating magnetic field. As the probe, along with its magnetic field, approaches a conductive material such as a metal test object, it induces a circular motion of electrons in the metal, similar to swirling water in a river. This phenomenon, known as an eddy current, circulates through the metal. The eddy current, in turn, generates a magnetic field in the metal, which interacts with the coil and its associated field through mutual inductance. Changes in the metal properties, such as microstructure, hardness, or material grade, alter the amplitude and phase of the eddy current and the resulting magnetic field. These changes affect the electrical impedance of the coil. The signals generated are processed by the instrument's software and plotted as impedance amplitude and phase angle. Any alterations in the material properties are then indicated on the screen and, in some cases, on an Andon system, providing a visual alert.

Features

- Cutting-Edge Eddy Current Technology: Our Eddy Current Machine Instruments leverage the latest advancements in Eddy current testing technology to precisely identify and sort materials based on their hardness and material properties.

- User-Friendly Interface: Our Eddy Current Machine Equipment is thoughtfully designed with the end user in mind, featuring an intuitive interface and clear displays that streamline operation and data analysis.

- Seamless Integration: The Eddy Current Instruments seamlessly integrate with a diverse range of material handling systems, facilitating easy incorporation into your existing production lines or quality control processes.

- Tailored Configurations: Our Eddy Current Machine can be customized to meet your specific sorting needs, offering options such as adjustable frequency ranges, multi-channel capabilities, and various probe types.

- 50 Program Memory to store test parameters for different parts.

- Reference part data storage

- Comprehensive data log

Specifications

| Frequency Range | 2 Hz-100Khz |

| Simultaneous Excitation | Up to 8 frequencies |

| Signal Gain | 0 dB to 86 dB in steps of 0.5 dB |

| Phase | 0 deg to 359 deg in steps of 1 |

| Isolated Digital Inputs & Outputs (Only in Line Model) | OK, Not OK, Trigger, Done |

| Communication Interfaces | RS485 (Only in Line Model), Ethernet, 2X USB2.0 |

| Test Coils | Round, Square, Rectangular, Customized |

| Touch Screen Size (In Lab model) | 12” |

| Display Connector (In Line model) | HDMI |

| Power Supply | 110V-220V AC, 47-63 Hz |

Optional features:

- QDAS system integration

- Benefits

- High-Speed Sorting: Engineered for high-volume applications, the Eddy Current Instrument can swiftly and accurately sort materials, enhancing the overall efficiency of your production processes.

- Non-intrusive: There is no alteration in any physical or chemical properties of the part under testing, and no indentation marks are left.

- Minimum skills required: Once the settings are configured, an unskilled operator can operate the machine.

- Uses very low voltage and current levels, ensuring complete safety for the operator.

- Reliability and Repeatability

- Low operation cost with no consumables required and very little power consumption.

- applications

- The Eddy Current Instrument is applicable across various industries and diverse applications, including aerospace, automotive, manufacturing, and metal processing.

- Segregation of forgings based on the heat-treat condition.

- Identification of hardness bands in automotive parts such as shafts, axles, connecting rods, hubs, couplings, steering parts, etc.

- Sorting by grade in the steel industry.

- Testing of raw materials in all industries utilizing metals as raw materials.

- Railway parts.

- Education and training.

Product models

Lab Model

Suitable for conducting tests in a non-production environment that demands the evaluation of various samples. Equipped with a user-friendly 9” touch screen interface for seamless operation. Portable and easy to transport from one location to another. Includes a durable plastic carry case for added convenience.

Line Integrated Model

Suitable for carrying out testing in a production environment where automated testing is required.

Can interface to any PLC using RS485 or Ethernet.

Digital I/Os for direct PLC interface.

Easy & open communication protocol.

A standard HDMI display can be connected.

Easy integration with the Andon system.