Case studies

Explore Our Impactful Case Studies. Witness the transformative power of our non-destructive testing and DFA solutions across industries. Discover how we've overcome challenges, optimized processes, and delivered exceptional results. Our real-world examples showcase our innovative approach and expertise. Unleash possibilities for your business by exploring our case studies today.

Case-Study #1

Problem Description:

Coincidently an operator observed a soft spot on a Steering Rack

Root cause was a water droplet from the cooling unit, occassionaly released during handling

40.000 units at risk, partly already at final assembly line in China, Germany, US

Client would not be able to manufacture replacement due to capacity constraints and lead time

40 DFA test devices were configured in 2 days, training of overseas operator included. 1 week the new procedure was qualified

100% inspection: 9 defective parts in 3 different batches found

Client Name:

<confidential>

Current Status:

- DFA inspection added to standard IPC.

- Integration into lab machine started, 1st machine in use

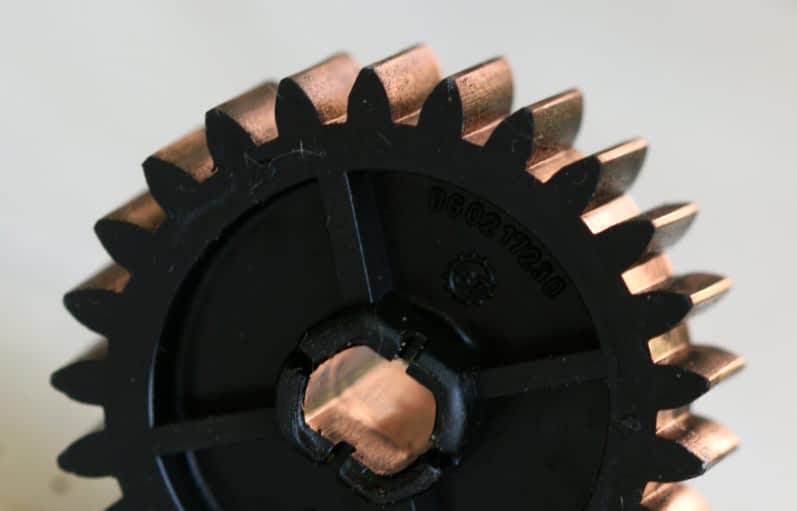

Case-Study #2

Problem Description:

Mix-up of hardened / non-hardened products occured

Products shipped already to warehouse in Poland

Task was to sort hardened from non-hardened

Device was set up on site within 5 minutes

Inspection of 3.000 pieces within 6 hrs

Inspection speed faster than part handling for un-packing / packing

Client Name:

<confidential>

Current Status:

- Problem solved

- Huge saving for Roop and Its partner in Poland

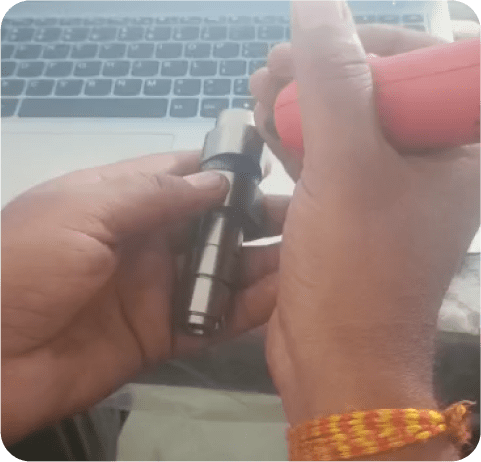

Case-Study #3

Problem Description:

Two Wheeler Camshaft was reported in Japan for Low Hardness issue.

Interestingly, low hardness was observed in only Exhaust camshaft, Intake Camshaft was OK.

Mahle Camshafts Pvt. Ltd.

Client Name:

<confidential>

Current Status:

- DFA added to MIS-P.