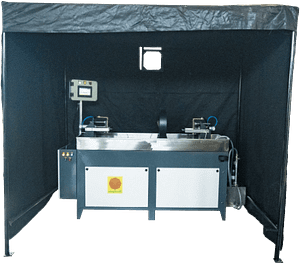

Multi-directional Bench Type Magnetic Particle Testing Machine

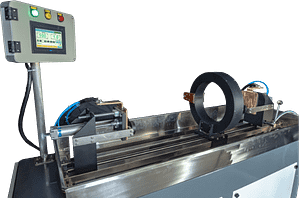

Magnetic Crack Detector Machine for Steel Bars

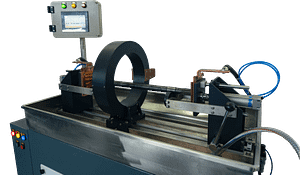

This wet, horizontal, bench-type unidirectional machine generates circular magnetization designed for inspecting both bright and black rolled steel round bars. Circular magnetization is achieved by clamping the bar directly between the headstock and tailstock, passing current through it. The machine is proficient in detecting longitudinal cracks exclusively. The headshot current can be switched between HWDC and AC for detecting subsurface and surface cracks. The machine operates semi-automatically, with all operations—loading, spraying, magnetization, demagnetization, and unloading—being automatic. The only manual operation is the inspection.

- The machine is equipped with nylon rollers designed for positioning and rotating the bar during the inspection process.

- The machine features an adjustable magnetization time of up to 2.0 seconds, enabling the thorough development of indications.

- Available in a range of part lengths and diameter sizes.

- The machine comes equipped with a darkroom frame, hood, and curtains, facilitating inspections with fluorescent inks.

Features

- Automatic loading from infeed bench.

- Automatic unloading from outfeed rollers to separate OK/Reject stacks.

- Magnetization, spraying, and inspection all on one station.

- PLC-Based Control. Fully automatic cycle for faster testing.

- 7-inch Touch Screen for control.

- Large Digital Ammeter with Retention.

- Operator-controlled automatic double shot

- 50 Program memory to store settings for different diameters.

- Error displayed on the touch screen for easy diagnostics.

- Digital, stepless current control.

- Heavy-duty transformer.

- Both sides have Pneumatic clamping.

- Stainless Steel liquid storage tank.

- Stainless Steel collection tray

- Reverse agitation bath system.

- Continuously movable tailstock with cam lock

- Integrated decaying-AC demagnetization with automatic control

- Feedback loop-based current control with current failure indicator.

- Standard make PLC & HMI. Easily serviceable.

Specifications

| Headshot Current Capacity | Models staring from 4000A going up to 6000A |

| Maximum Part Length Accommodation | Staring from 5m going up to 10mm |

| Maximum Part Diameter | Staring from 16mm going up to 160mm |

| Maximum Part Weight | 1200Kg |

| Storage Bath Capacity | 50-150 L |

| Shot Time | Adjustable from 0.5 sec 2.0 sec |

| Power Supply | 3 Phase 4 Wire 415V AC/220V AC |

| Frequency | 50Hz or 60Hz |

| Pneumatic Pressure Required | 4-6 Kg/cm2 |

| Control Voltage | 24V DC |

| Touch Screen Display Size | 7” Diagonal |

- Benefits

- Fully automated operation

- Digital current control based on SCR technology ensures accuracy and precision

- Feedback loop ensures consistent repeatability

- Reverse agitation system maintains continuous dissolution of powder in the carrier fluid

- Pneumatic clamping mechanism guarantees spark-free operation

- 7-inch Touch Screen for enhanced operator comfort

- PLC-controlled operation for quicker and reliable testing

- Low voltage output prioritizes operator safety

- Operator-controlled Poka yoke for managing the demagnetization cycle

- applications

- Bright Steel Bars

- Black Steel Bars

Product models

| Model | Head Shot Capacity | Maximum Bar Length | Minimum Bar Length | Maximum Bar Diameter | Minimum Bar Diameter |

| MK-40-400-BRT | 4000A AC & HWDC | 4m | 2m | 75mm | 16mm |

| MK-50-600-BRT | 5000A AC & HWDC | 6m | 2m | 90mm | 25mm |

| MK-60-C-800-BRT | 6000A AC & HWDC | 8m | 2.5m | 120mm | 50mm |

| MK-80-C-1000-BRT | 8000A AC & HWDC | 10m | 3m | 160mm | 75mm |