DFA (DIFFERENTIAL FLUX ANALYSIS)

Brief Description of DFA

DFA stands for Differential Flux Analysis. It is our Patented and German based sensor technology for fast quality inspection of Metallic parts.

DFA is automatable, easy to integrate in manufacturing and does not impact cycle times.

DFA is easy to train to the operators.

DFA is a non-destructive testing for ferrous and non-ferrous parts.

DFA is quick and sustainable solution to increase quality in manufacturing.

DFA enables 100% in-process inspection.

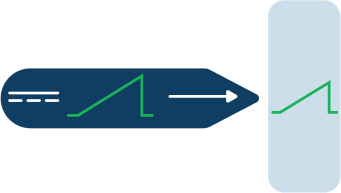

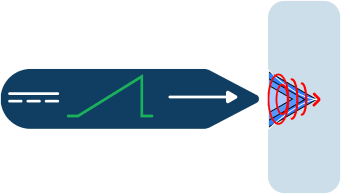

Excitation with a ramp-shaped electromagnetic signal

Formation of eddy currents in the sample

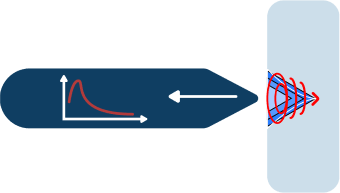

The sensor measures the voltage-time curve of the emitted field – the inductive fingerprint

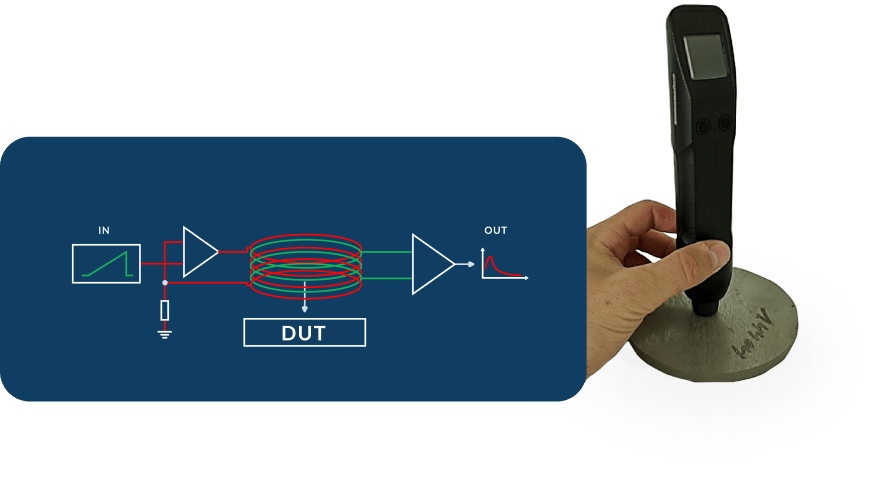

What is the invention behind DFA?

DFA compensates unwanted external effects (like distance and orientation) on ferrous and non-ferrous parts and allows a repeatable and process stable measurement.

DFA’s compensation is based on the combination of a hardware-controlled lift-off of and a pulsed-ramped-linear current excitation.

Advantages of DFA over Conventional Solutions

Conventional Solutions

- One specially designed coil per application

- Measurement result represents the average value

- Not Portable

- OK part always to be present for comparison with the sample

- Testing of components at PPAP stage not possible

DFA

- No special coil required. One sensor head for various applications.

- Point /line measurement possible resulting in pointed values at the desired area

- Portable version available

- OK parts can be calibrated and its data can be stored in the system

- Easy testing of components during PPAP with DFA Lab equipment